Let us make this planet a better place to live.

Sustainability is Longtermism, companies need to act economically, ecologically, and socially in a comprehensive sense, to achieve Longtermism. Operating in ways that, at a minimum, meet fundamental responsibilities in the areas of human rights, labour, environment, and anti-corruption. It is this envision that makes successful growth.

Aavvie® has a mindful team that understands the value of resources, as the ancestors say we just are the custodians of the resources and pass them on to the coming ages.

Aavvie® believes in and upholds the responsibility to respond to climate change, it also recognizes the key challenges and strives to find out the remedies to bind solutions. Before the people, civilizations, and industries nature had its balances, which we believe have been compromised due to the human interventions. Aavvie® reconciles dreams of creating such an ideal world, where the developmental activities stay complemented by the nature.

We support UN Global Compact Principles,ie Businesses should support a precautionary approach to environmental challenges;undertake initiatives to promote greater environmental responsibility, and encourage the development and diffusion of environmentally friendly technologies.

Aavvie® has been planting trees for the future, We have kept a target of planting 1 million trees by 2025 across the country.

Reducing the consumption of water, Toilets in the Manufacturing Plant are vacuum suction toilets just like what we have in flights and ships. It drastically reduces water usage and also is more hygienic. Just imagine having 100s of employees using it.

Using Solar panels to power the factory, could reduce energy dependence on the grid.

Rainwater harvesting systems; would create a surplus of water at the same time this technique could be used for groundwater recharging benefitting the local communities as well.

Convert to EV vehicles for transportation of goods in short distances

Things are well-sorted before procuring the daily use items like stationaries, more eco-friendly items are used, and plastic-based use and throw items are avoided.

Use of Bio-degradable materials in the cafeterias like paper or bamboo straws, and paper/bamboo tumblers instead of plastic ones.

In the office: Minimizing paper usage and going digitally.

Motion sensing lights and faucets in toilets and washrooms; This will enable a just-in-time approach to water & electricity usage.

We give priority to people than business, we endeavor in providing the best and world-class facilities for the people in the family. They are treated with the highest standards. From the highest-ranked executive to the low ranked worker equal privileges are given to all, we believe;that ‘liberty is their right’.

We are able to achieve this cohesiveness among employees by carefully curating the recruitment process, we always give preference to those people who have better social skills and are ready to amalgamate into a team.

We believe in providing quality work-life to workers so that they return their full to the company. We want them to work peacefully as well as wholly. They should work open-mindedly and happily, thereby we can expect the best results and perfection from their end.

In short, professionals make products “for professionals”.

Safety is our mindset throughout our operations. We work towards a zero-accident workplace by setting ambitious targets for continuous improvement, developing consistent safety practices and competencies at every level, and creating a culture of responsibility and accountability for all employees.

Axes are kept sharpened to achieve success, The people at Aavvie® regardless of the position will undergo training routinely. We believe in keeping the axe, sharp to chop ahead through the challenges. Training complements safety and focuses on continuous improvement.

In the path of Sustainability, Process is the step to reach the destination For a company it is critical to have clear procedures in its operation. We work every day to further improve our product quality, act with integrity and transparency, and deliver on our value proposition. Organizations are making significant strides to improve their business processes because they recognize that businesses perform better when their processes are aligned with overall organizational objectives.

As a business, you can engage in several different activities to become sustainable: Reduce waste, prevent pollution, use clean energy, conserve water, reduce water consumption, encourage trees on the planet, and use sustainable materials so that their products will be sustainable for years to come.

On the Road to Sustainability, we give preference to, problems and challenges in the industry and how we could find a solution to them.

Inspired by the Japanese

-Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It derived from Toyota’s 1930 operating model “The Toyota Way”.

When done correctly, lean can create huge improvements in efficiency, cycle time, productivity, material costs, and scrap, leading to lower costs and improved competitiveness. can improve how a team works together, inventory management, and even client interaction.

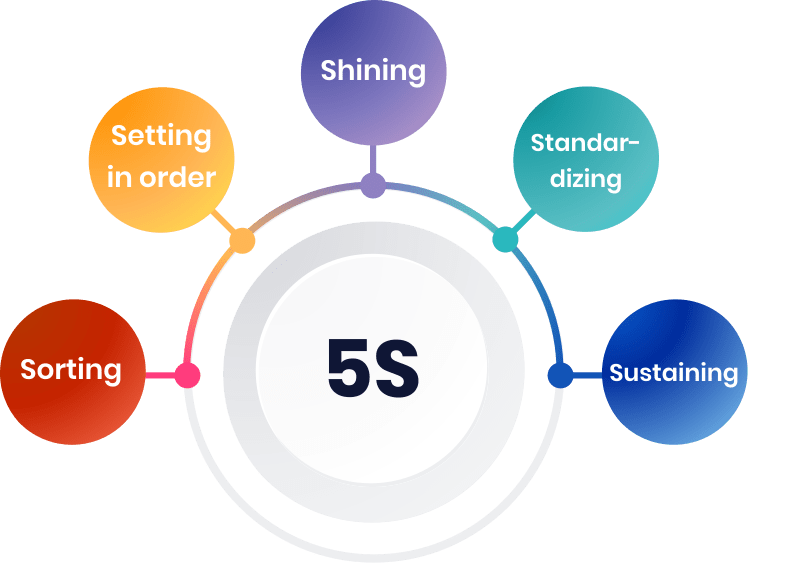

5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury.

5S began as part of the Toyota Production System (TPS), the manufacturing method begun by leaders at the Toyota Motor Company in the early and mid-20th century. This system, often referred to as Lean manufacturing in the West, aims to increase the value of products or services for customers.

Six Sigma is a technique used to improve overall quality of production output. Originally developed by Motorola, the six sigma process is used to remove causes of variation and defects in manufactured products, and is a universally recognized as an important Lean Manufacturing concept.

When done right, Six Sigma can enable:

While Lean helps in making processes more efficient, Six Sigma helps in finding the root cause of problems, and 5S helps in removing items that are no longer needed – helping keep the business streamlined and organized.

Together Lean, Six Sigma and 5S can lead to not just individual process improvements but improvements across the entire value chain – via continuous defect and waste reduction.

-Meaning “continuous improvement”, kaizen targets human resources and processes so as to anchor industry for long-term and successful operation. Kaizen is a Japanese term coined in the period after World War II when businesses were trying to cope with the effects of the war. “Kai” translates to the word “change”, and “zen” means “good”. Kaizen produced significant results for companies and has become a popular production philosophy all over the world.

In Lean manufacturing, Kaizen is the practice of continually making small, incremental improvements for a safer, more productive, and more efficient workplace.

With Kaizen

In short, Our Sustainability goal on Process is to improve

Safety and fair opportunities, talent development, lifelong learning, and a diverse and cosmopolitan corporate culture are among our unchanging guiding principles. With these activities, we contribute to successful business development in the long term and at the same time support the United Nations Sustainable Development Goals.

All Rights Reserved to Aavvie

AAMI standards require a surgical gown to pass ASTM International F1671 in the critical zones in order to be labeled an AAMI level 4 surgical gown. What areas are included in the critical zone? There are typically four different areas that must pass within the critical zones, including two in the front chest and two on the sleeves. If a product passes ASTM InternationalF1671 in all applicable areas, then it qualifies as an AAMI level 4 surgical gown.